How Localisation and AI Can Build Resilience In Uncertain Times

“We are living through unprecedented times” – a phrase that everyone has become familiar with over the last two years. It represents risk, volatility and uncertainty, all of which present challenges to building and maintaining stable supply chain networks. In a recent survey of 200 supply chain leaders, EY found that only 2% believed they were fully prepared to navigate the COVID-19 pandemic, while 57% reported that the uncertainty had caused serious disruption to their operations [1]. It can be easy to identify best-practice in hindsight, but the hard task of planning for future uncertainty is where true value is found. The question is, how does one prepare for the unknown?

Producing resilient supply chains is a top priority for many CEOs and executives in the face of increased volatility. In their 2021 CEO Outlook survey, KPMG found that 59% of small-medium enterprise CEOs are looking to ensure their supply chains are resilient enough to combat future uncertainty [2].

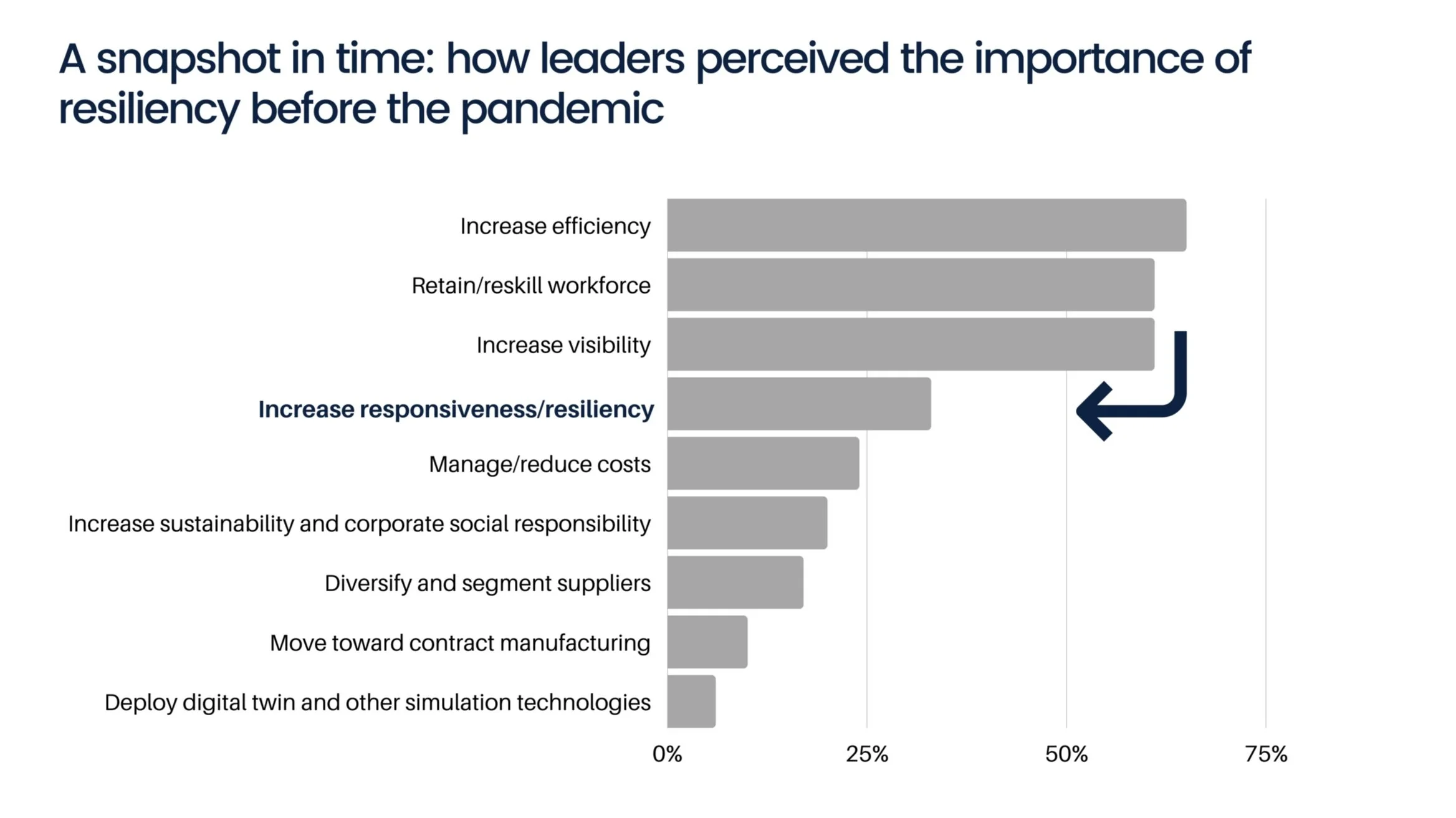

Prior to the pandemic, increasing efficiency, retaining workforce and increasing visibility were identified as the top three priorities for 2020 in the 2019 EY supply chain survey, with increased responsiveness/resiliency in fourth place [1].

Source: EY Supply Chain Survey (2019)

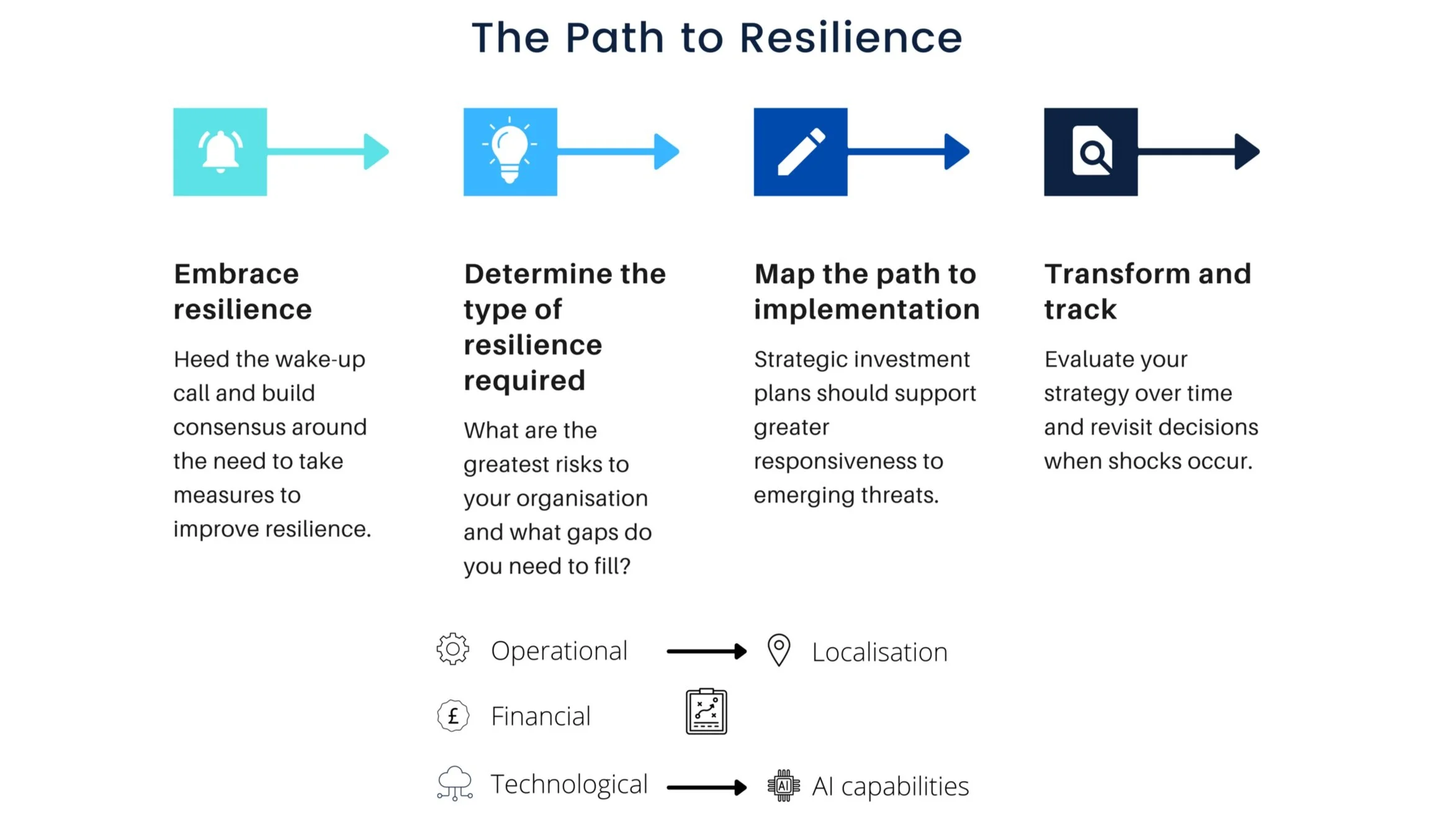

Supply chain disruptions amidst the pandemic have emphasised the importance of building even greater levels of resiliency, but what can leaders do to achieve this?

Two Key Strategies to Increase Supply Chain Resilience

1. Transition From Global to Local

Whether to globalise or localise a supply chain has been a topic of debate for years. Companies that adopt a globalised approach can reap the benefits of standardisation and economies of scale, whereas localised supply chains can increase control over their suppliers and improve predictability [3]. In a market where consumers are becoming ever more conscious about sustainability, the sourcing of environmentally friendly materials may be crucial to deriving a competitive advantage during times of uncertainty. While global supply chains are bound by strict regulations, they rely on long-distance travel across countries. Local supply chains, on the other hand, maintain the freedom to source from nearby suppliers, reducing transport and unnecessary energy wasted on storage [4]. There now appears to be a consensus between leaders on the approach to take. A McKinsey & Company survey found that 90% of supply chain leaders expect to move towards localisation during the next three years [5].

The three factors below are vital to successful localisation:

Assess the ‘essential’ and ‘preferred’ elements of your global supply chain and use this insight to create a local model. When uncertainty looms, it is the prioritisation of those essential elements that will be critical to its survival.

Identify which suppliers are core to your localisation process and deepen relationships with them to win preferred customer status. In the wake of crises, accelerated payments or guaranteed loans can give key vendors a lifeline.

Onshore if you can, nearshore if you can’t. This will provide tighter control and flexibility when logistics networks experience problems.

2. Invest in Artificial Intelligence

We are currently experiencing the 4th major revolution. Unlike its ancestor, the industrial revolution, this epoch of change does not concern itself with oil and steam, but code and robotics. Automation has already enabled higher outputs and greater standardisation of production across the entirety of supply chains. Now, machine learning through artificial intelligence (AI) can evaluate new information against stored data to design models that accommodate multiple eventualities. These newly available data insights can provide valuable guidance in times when a strategy is not always clear.

In times of uncertainty, organisations that have invested significantly in developing their AI stand out from the crowd. It is estimated that successfully implementing AI into supply chains has enabled early adopters to improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%, compared with slower-moving competitors [6].

AI can be used to optimise supply chains in times of uncertainty in these crucial areas:

Adjusting order sizes or frequency are key defensive levers for accurate inventory management. Strategic stockpiling to ensure sufficient backup inventory or reducing SKUs to improve efficiency can minimize the impact of supply-side disruption. AI systems can analyse huge datasets to identify supply and demand shifts, identifying optimal inventory levels.

AI-enabled automation is driving efficiency in supply chain logistics as smart, connected warehouses integrate with trackable, end-to-end movement of shipments. AI systems can solve warehouse issues especially quickly with the help of robotics. DHL is deploying robotics capabilities across all regions to enable (un)loading high areas and trailers, with all tracking data feeding into 'MySupplyChain' software for total visibility [7].

Procurement teams can use digital analytics to quantify the extent to which market forces will affect the prices of materials. Introducing cloud platforms and AI to improve visibility along the entire supply chain can enable supplier collaboration to drive joint efficiencies in the face of price shifts.

The market is calling for technology-enabled services providers who have capabilities in the provision of reliable, trackable, on-demand, and integrated data solutions. Those companies that get smarter through increased automation are able to build in predictive outcomes and responses to navigate volatility.

The COVID-19 pandemic quickly descended upon us with devastating effects. Now more than ever, we are able to reflect on the impact of uncertainty on supply chains and prepare for future volatility. Leaders are looking to future-proof their operations, building resilience by favouring local supply chains and investing in AI to mitigate risks. Organisations that have prepared through investing in resiliency will be rewarded over the long term.

Words by Jonathan Brownfield

References

[1] https://www.ey.com/en_gl/supply-chain/how-covid-19-impacted-supply-chains-and-what-comes-next

[2] https://home.kpmg/ca/en/home/insights/2021/10/future-proofing-supply-chains.html

[4] https://www.bcg.com/publications/2020/supply-chain-needs-sustainability-strategy